Make reference to Figure D. HEPA filters are set up in the upper encounter on the plenum along with the plenum is pressurized with filtered air. The ceiling mounted HEPA filters Use a experience velocity as many as one hundred-120 toes for every m inute.This is often considerably larger when compared to the HEPA filters serving the remainder of the cleanroom. The filters are generally equipped with air by a duct distribution network consisting of rectangular or spherical trunk ducts and versatile or rigid round branch ducts. Complete coverage, common for Class one hundred cleanrooms, or partial protection, for greater class (a lot less stringent) cleanrooms, can be achieved making use of two'x 4' lay-in HEPA filter modules mounted in the ceiling.

The power layout need to guidance the process contained within the cleanroom. Though an oblong shape is simplest to accommodate, other designs can be incorporated into the ability providing acceptable attention is compensated to airflow styles.

Editors deliver breaking news, solution launches, and innovations, in addition to commission exclusives on technological traits from industry specialists

JW Winco’s handbook will assistance designers and engineers with the most important number of normal parts.

Set up qualification verifies which the cleanroom, right after installation, is consistent with the required design. It ensures that the cleanroom components and systems are the right way mounted and operational.

05 in. W. C.). Exactly where a number of cleanrooms of various amounts of cleanliness are joined as a single complex, a positive force hierarchy of cleanliness amounts need to be managed, together with airlocks and gowning rooms. Notice that for particular procedure it may be fascinating to have a unfavorable tension relative to encompassing ambient in one or more rooms when containment is An important problem. A "room-with-in-a-room" might ought to be designed to realize this adverse tension nonetheless continue to meet the needs of clean Procedure.

The following ideas are intended to presume which the amenities, when used effectively, will meet up with the airborne Particulate Courses for Cleanrooms and Clean Zones, and can provide an atmosphere that does not negatively have an effect on bio-pharmaceutical processes carried out therein.

It is a good quality write-up not just for pharma students but additionally for me as a closing yr building providers engineering student. Many thanks

Clean rooms in pharma industry are arias which are specially designed to lower and eradicate, particulate and microbial contamination in surroundings in aria utilized for manufacturing of pharmaceutical dosage types, especially parenteral dosage forms that are required to be injected directly into entire body and blood stream are required to be totally free from practical microbial contamination as well as adjust to the prerequisite of particulate issue present in addition to need of absence of pyrogen.

We also use third-get together cookies clean room guidelines in pharma that assist us evaluate and understand how you utilize this Site. These cookies is going to be saved within your browser only with all your consent. You even have the choice to decide-out of such cookies. But opting outside of some of these cookies may well have an effect on your searching knowledge.

HEPA filters may be mounted in the facility either in just an air handler or within the inlet to your plenum previously mentioned the cleanroom or within the cleanroom ceiling. High velocity HEPA filters, that is, filters that has a facial area velocity up to 500 feet for every moment, are frequently installed in air handlers serving Class 100000 cleanrooms. Consult with Figure here C. In the course of the design stage care really should be taken to offer use of equally the upstream and downstream deal with of those filters to permit periodic tough and leak tests. To provide HEPA filtered air in excess of a limited location, in just a larger controlled Place, a ceiling mounted plenum may very well be employed. This plenum has an air distribution indicates at its decreased face that permits air for being launched within a unidirectional manner in excess of the critical approach area.

Clean rooms are crucial to your pharmaceutical industry for preserving item high quality, protection, and regulatory compliance.

The frequency of requalification depends on the cleanroom quality. Quality A and B parts really should be requalified every 6 months, when Grade C and D locations need requalification each twelve months. Requalification is likewise important soon after adjustments, remedial actions, or as based on threat assessments.

Cleanroom classification boundaries are generally standardized based upon industry standards and regulations. On the other hand, in some instances, restrictions could be modified based on an intensive hazard evaluation and scientific justification, taking into consideration the precise requirements on the producing procedures.

Hallie Eisenberg Then & Now!

Hallie Eisenberg Then & Now! Alisan Porter Then & Now!

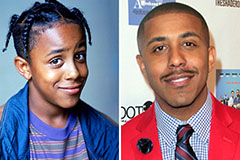

Alisan Porter Then & Now! Marques Houston Then & Now!

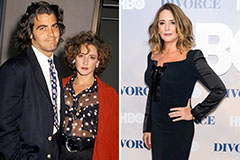

Marques Houston Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!